The frame of a house does for the structure what our skeletal system does for our bodies. It provides support and ensures that the structure can bear the weight of all the other materials and contents which will be added to it. Since the frame is one of the fundamental elements of the structure, naturally there are strict standards which must be adhered to, so that it results in a sturdy building.

There are traditional methods of residential wood framing used in construction; however, novel methods now exist, especially with the development of new tools and design methods. If you employ skilled residential wood framing contractors for your project, you will be sure to get some exceptional work.

Here are 7 alternative ways you can add stability to the structure to your home, outside of the conventional methods.

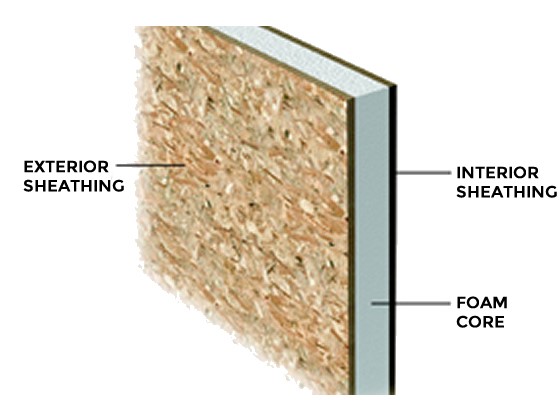

- Use Structural Insulated Panels or SIP

Image Source: Buildevergreen.com

These panels are created from two sheets of oriental strand board or OSB between which rigid foam, to serve as insulation, is placed. The oriental strand board used in residential wood framing is made from small bits of discarded wood bonded together with a strong adhesive to create sheets. OSB or plywood may be used for similar functions.

These panels can be used to cover framing, in ceilings and on walls, or may serve as structural support on their own. Since they already come with insulation, it reduces the cost of having to add insulation as a separate step, and it is also energy saving. This makes it a very effective go green solution. These panels come with already cut out spaces for windows and doors, as well as spaces to accommodate electrical wiring and conduits.

- Use Wood Structural Panels with Continuous Sheathing

This is an advanced method of wall bracing which allows for the use 24 inch spacing between the center framing studs, whereas the building code limits conventional spacing to 16 inches between studs. This method results in greater structural support for the walls than would be achieved with conventional wall bracing techniques. Another improvement is the use of 2 x 6 wood for framing instead of the traditional 2 x 4.

- Use Sheathed Wood Panels for Siding Attachment

Image Source: eichlersiding.com

This method results in significant savings for wood framing contractors and by extension, the homeowner. The savings come from the use of less siding products being required for attaching the studs. The sheathing makes it possible for stud spacing to be 24 inches apart instead 16 inches and also serves as a base support for fastening the studs instead of siding products.

The use of plywood for wall sheathing is also very cost effective, energy efficient and offers good structural support. Wall sheaths are easy to insulate, facilitate windows easily and also offer good protection from the natural forces.

- Use Two Stud Corner Framing or Three Stud Insulated Corner Junctions

Using these materials in the corner of the residential wood framing structure, along with drywall clips or ladder blocking material, results in the elimination of the cavity or space which is generally created when conventional methods are used. With space now eliminated, this results in better insulation and also savings for future energy bills to come.

- Use Ladder Junction Tee Intersections

The junctions are used at wall intersections for vertical spacing. Using the ladder junction results in the use of less wood for studs, fewer wall joints and also less blocking material being required. Unlike conventional methods, this is much easier to insulate and is very effective at keeping air out and resulting in efficient energy use. These junctions also allow for the installation of a continuous drywall.

- Use Insulated Headers

Image Source: Greenhomethoughts

Headers are used to provide support for nailing or attaching other materials which will be used to cover certain areas of the framing. Conventional headers are not insulated which causes loss of air and inefficient insulation. The headers which come with a cavity can be easily insulated and facilitate greater energy efficiency. They are also sized according to the amount of load they will bear, contributing to the overall strength of the residential wood framing.

- Use Modular Units to Cover Traditional Framing

Using factory built modules over traditional residential wood framing is extremely beneficial for saving time and cutting cost. These modules come already finished on the interior and eliminate the need for additional insulation. If you are looking to go green, this is an excellent option to go with.

The beautiful thing, too, is that they are fully customizable for your home construction project, but the price will vary based on your requirements. Ensure that you are using a company with a good reputation for producing quality products and also be diligent when inquiring about the various materials they offer.

Speak openly and candidly with your residential wood framing company about their ability to provide the options you are looking to employ in the construction of your new home. They will also be able to provide you with valuable guidance and point you in the right direction.

Get in touch with us if you are in need of Residential Framing Contractors in Massachusetts or Connecticut.